Customer damage refers to instances where compressor failure is caused by improper installation, mishandling and / or incorrect system application.

Compressors are susceptible to damage whenever failures occur within the A/C system. System failsafes such as Pressure Relief Valves (PRV), Thermal Protection Switches (TPS) and High / Low pressure cut offs are often used to reduce the possibility of compressor damage under abnormal system conditions. These devices limit damage to A/C components by making the system inoperable whenever a severely abnormal condition develops.

When a returned compressor is analyzed for failure responsibility, the physical condition of the compressor is examined to determine if the compressor was subjected to handling damage and / or improper installation. If the compressor has external indications, or shows evidence that it was subjected to extreme conditions which caused the failure, then the cause of the failure may be determined to be customer damage.

Customer damage includes but is not limited to the following:

A) Overtorquing of mounting bolts which may break compressor ear mounts.

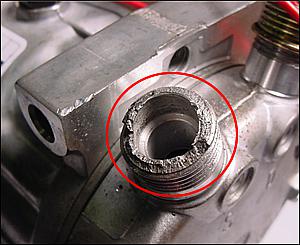

B) Overtorquing of hose fittings which can result in stripped threads or broken ports.

C) Improper field service. Parts that are incorrectly replaced or installed can result in subsequent compressor failure.

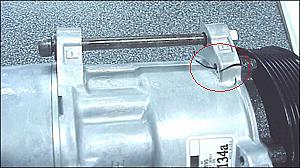

D) Mechanical damage to the clutch, scratches, nicks, dents, air gap modified, lead wires pulled out, pinched, cut etc.

E) Mechanical damage to the compressor cylinder block.

F) The addition of non approved chemicals which may cause system and / or compressor malfunction.

G) Improper packaging or handling of the compressor.

H) Improper modification of the compressor i.e. painting, plating, polishing etc.